Fayetteville, Arkansas

March 11, 2008

|

|

Dr. Rusty Bautista,

post doctoral research associate, collects samples of

rice in a research project to determine the effects of

night time air temperatures and moisture content at

harvest on the milling and functional quality of rice.

Photo by Howell Medders

|

|

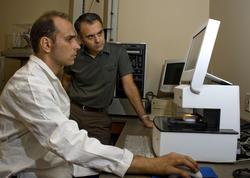

Research technician

Mohammed Saleh, left, and Dr. Jean-François Meullenet,

associate professor of food science, use a near-infrared

diode array analyzer to predict quality characteristics

of rice samples. Photo by Fred Miller

|

Scientists in the

University of Arkansas

System's Division of Agriculture are taking a systematic

approach to research on issues of post-harvest rice quality.

Several lines of research, beginning with the effects of

nighttime air temperatures and moisture content at harvest on

post-harvest quality, are coming together to give rice breeders,

growers and processors critical information to improve rice

varieties and products. The information will also help growers

and processors make decisions aimed at improving the returns on

their production investments.

Food scientists Terry Siebenmorgen, Jean-François Meullenet and

Ruben Morawicki are joining forces with rice physiologist Paul

Counce and rice breeders Karen Moldenhauer and James Gibbons in

a research effort supported by the Arkansas Rice Research and

Promotion Board.

“Harvest moisture content and nighttime temperatures during

kernel development typically make a huge impact on milling and

functional quality,” Siebenmorgen said.

Milling quality refers to how rice kernels stand up to drying

and the milling process — the degree to which they break apart

or remain intact. Functional quality influences how the rice

will behave during processing into food products, including

parboiling or “puffing” for cereal.

Siebenmorgen’s assertion is based on five years of data

collection. His qualifier, “… typically,” is the target of

ongoing research to identify the environmental factors that

contribute to the impact of harvest moisture content.

Linking up with Moldenhauer and Gibbons, who supervise the

Arkansas Rice Performance Tests (ARPT), and Counce, who provides

growth stage analyses, Siebenmorgen will examine the impact of

nighttime air temperatures and varying levels of moisture

content on six varieties and hybrids of rice grown in Arkansas.

“Drs. Moldenhauer and Gibbons are adding three extra

replications of each of six specific entries in the ARPT plots

at each of six different Arkansas locations.”

Samples from each of those additional replicated plots will be

harvested at six different moisture contents, Siebenmorgen said.

Two sensors that record nighttime temperature and relative

humidity from 50 percent heading to final harvest will also be

located at each location.

“Primarily, we want to quantify how bulk physical and chemical

properties, and the kernel to kernel distribution of those

properties, change at different moisture contents,” Siebenmorgen

said.

Six samples from six varieties at six locations, all replicated

three times, will result in hundreds of samples. The timely

harvest of these samples at six, spread-out locations represents

a tremendous challenge that is being met by Rusty Bautista and

Redentor Burgos, rice scientists in the Rice Processing Program.

Siebenmorgen will be looking at how these samples perform in

drying and milling tests. Meullenet will study the impact of

harvest moisture content and nighttime temperatures on

functional and sensory quality and Morawicki will study the

impact on cooking quality.

The chemical tests required for the functional quality study

alone would require hundreds or thousands of hours of lab work

using conventional chemical analysis, Meullenet said.

To speed things up, Meullenet uses a near-infrared diode array

analyzer that can predict results for milling quality

characteristics with a six-second test.

The instrument exposes rice samples to near-infrared light of

different wavelengths and measures the difference between light

absorbed and light reflected by the sample, Meullenet said. The

results are indicative of chemical characteristics in the rice.

Meullenet is working on developing calibrations that will also

give accurate results for functional quality characteristics.

The most important of these for functional quality are texture,

viscosity of rice flour and protein content.

Meullenet and research technician Mohammed Saleh are testing

rice samples from the variety testing program at Riceland Foods

and comparing the results against those measured by conventional

chemical tests already performed by Riceland.

“Riceland tests about a thousand samples a year using

conventional chemical tests performed by three full-time

technicians,” Meullenet said. “Once we determine the proper

calibrations, we’ll be able to test that many samples in a day.”

His goal will be to develop prediction calibrations that will

grade rice samples in relation to a “gold standard” of quality,

like Bengal, a rice variety considered to have near ideal

quality for some food applications involving puffing.

Siebenmorgen and Meullenet also want to make the massive and

growing trove of rice quality data easily accessible to growers

and processors, who can use it to make decisions about choice of

variety, most cost effective harvest moisture content and other

considerations. Rice breeders can also use the data to help

evaluate a breeding line for its potential as an improved

variety.

The team is developing a Web site that will allow easy,

searchable access to the data, Siebenmorgen said. They also

would like to develop a spreadsheet program that will allow

growers or processors to input variables, such as variety or

hybrid, growing location and drying costs, and provide

historical data on properties and processing qualities.

“It’s a tool for determining which decisions will help hit an

‘economic peak’ for producers and processors,” Siebenmorgen

said.

“The great thing about taking this systematic approach,”

Meullenet said, “is the integration of the effort across

disciplines. And we’ll be able to follow the performance of

specific rice varieties year after year.” |

|